7チャンネルタッチタイププログラマブル温度コントローラー

TEMP2000M SERIES

It is a multi-channel programmable controller which supports high-definition TFT-LCD touch screen, SD card and multi-channel control function

-

Selection of channel for system

Control of 3 channel / 5 channel /7 channel and selection of recording

-

High accuracy

Precision control with 18bit A/D convertor

±0.1% of full scale ±1 digit

-

Control PID of a variety

Temperature control PID group(5 Zone PID + 1 Deviation PID or 6 Seg PID)Zone, Deviation PID etc. Various PID offer

-

Various unit displays

Available 12 kinds of various unit to display under DCV sensor (˚C, ˚F, EDIT, %, ㎩, ㎪, %RH, ㎷, V, Ω, mmHg, kgf)

-

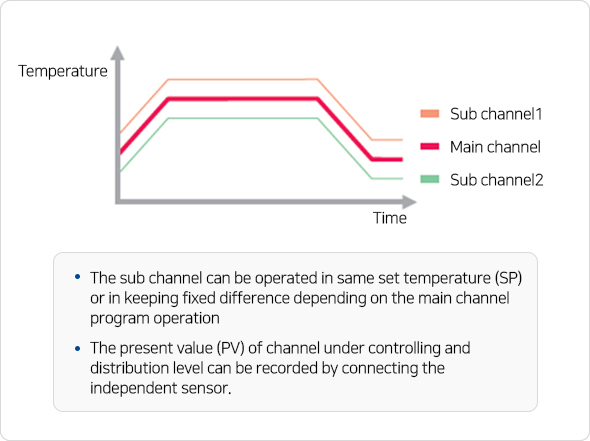

Diverse control method in sub channel

Available for independent control and sync controlAvailable for setting the individual operation calibration datain sub channel during sync operation

-

Supporting the heater short (12A, 50A and 100A)

Display by measuring the current flowing in the heater andavailable for short alarm output Use of 800:1 CT

-

Total 6 channel digital recording

Real time monitoring and data saving for the present data of main channel,setting data and the present data of output quantity and sub channel

-

Multi-language system

Supporting of various languages of korean, english, Chinese, Japanese and russian

-

SD memory card support

Data storing into the SD memory card and available for up/down of the set parameter

-

Powerful communication

Basic include RS232C/485 serial communication (Communication speed 115,200bps) Ethernet support option

-

Operation time management

Display of the operation starting time, estimated termination time and operation time up to now

-

Free PC software

Free PC multi-monitoring software for communication and SD viewer for data management of SD data

Supporting SD memory card

-

Selectable Initial screen

User can choose appropriate initial screen

-

Editable Error Screen

Self-designed picture can be used

-

Electronic Album

Company and product profiles can be displayed

-

Data recording with SD card

Data acquisition of process value.

Up/Download parameter and pattern data.

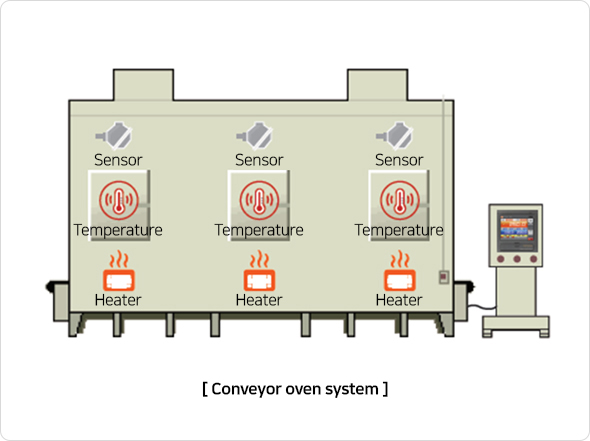

Sync Control

It is an operating method of synchronizing the operation state and setting value (SP) of main channel with sub channel.

Application system: Electric furnace, continuous furnace and ripple lower

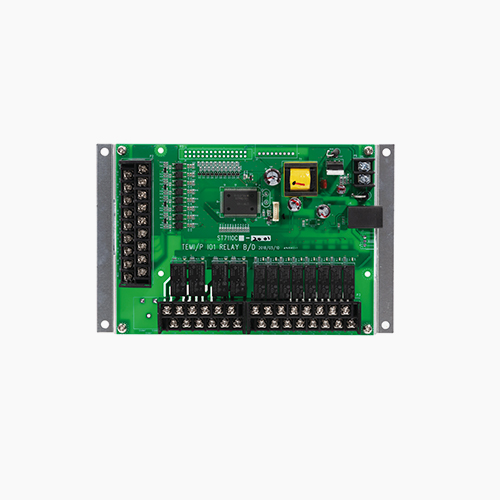

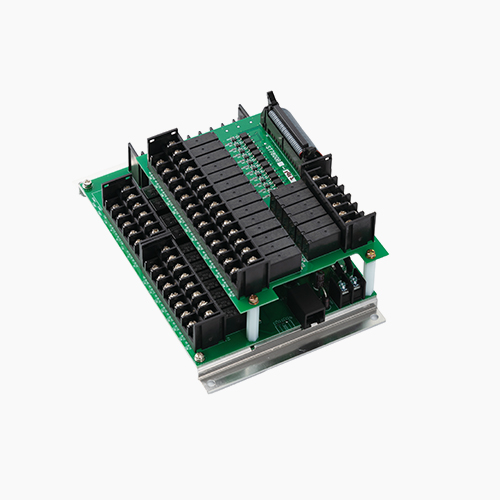

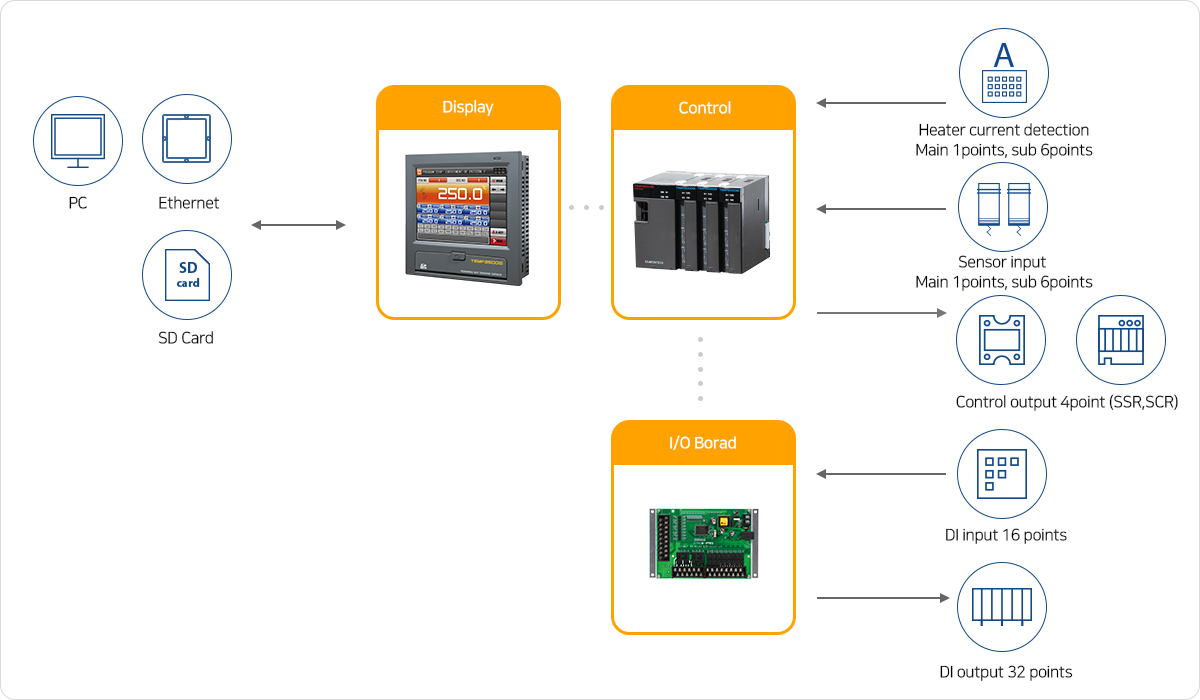

Separated hardware

Configuration separated by display, control, and input / output board

Available to mount panel mount and VESA mount

Various system configurations and work ability

| Group | Item | TEMP2500M | TEMP2700M | TEMP2000M |

|---|---|---|---|---|

| Screen | Display | 5.7* TFT-LCD |

7.5* TFT-LCD |

- |

| Resolution | 640(W) x 480(H) |

- | ||

| Language | Korean, English, Chinese/Korean, English, Japanese |

- | ||

| User screen | Change of initial screen, Electronic album function |

- | ||

| Mount type | Panel mount, VESA mount(MIS-D 75) |

- | ||

| Operation screen | Basic screen, available for making drawing which meets customer needs(Option) |

- | ||

| Control channel | Main channel | 1 channel |

- | |

| Sub channel | - |

Selection of 2/4/6 channel |

||

| Analog input | Input quantity | 1point(Universal input) |

2/4/6point(Universal input) |

|

| Sensor type | TC |

K, J, E, T, R, B, S, L, N, U, W, Platinel Ⅱ, C |

||

RTD |

Pt100(IEC), Jpt100(JIS), 1/100 Displayable |

|||

DCV |

0.4~2V, 1~5V, 0~10V, -10~20mV, 0~100mV (4~20mV, 0~20mV, External resistance 250Ω, 500Ω Attach) Scale : -1999 ~ 30000 |

|||

| Sampling period | 250ms/Channel |

|||

| Input accuracy | ±0.1% of full scale ±1 digit |

|||

| Analog output | Output specification (Max. 2point) |

Voltage output(SSR) 2points |

ON voltage : 15V DC (Load resistance:Min 600Ω/pulse width: Min 5ms) |

1point/Channel |

Current output(SSR) 2points |

4~20mA DC(Load resistance: Max. 600Ω) |

|||

| Output type | Control output/Transmission output(PV, SP)/Auxiliary output |

Control output |

||

| Digital input | Contact point specification |

Basic 16points(Contact point capacity : Max. 12V DC, 10mA) Selection of operation for A or B point

|

||

| Contact point function |

Run/Stop/Hold/Step, selectable run patterns, set DI detect delay time, select DI error monitor(text or picture)

|

|||

| Digital output | Contact point quantity | Basic 12points(A contact point relay 8points + C contact point relay 4points), Option(A contact point relay 20points) addition function |

||

| Contact point specification | Normal open(Max. 30V DC/1A, 250V AC/1A), Normal close(Max. 30V DC/1A, 250V AC/1A) |

|||

| Signal type | Inner signal(8points) On/Off signal(7points) Logical signal(3points) Error signal(1point) User signal(1point) |

Alarm signal (2points/channel) Heat break alarm signal (1point/Channel) |

||

Time signal(8points) DI signal(16points) Sensor open signal(1point) Hba signal(1point) Ref signal(2points) |

||||

Alarm signal(4points) Manual signal(16points) Wait signal(1point) Up· Soak· Down signal(each 1point) |

||||

Seg alarm signal(4points) Run signal(1point) Fix timer signal(1point) Fix· Programmable end signal(each 1point) |

||||

| Heater current detection |

Type | 12A, 50A, 100A |

||

| CT sensor/Accuracy | 800:1/±3% of full scale ±1 digit |

|||

| Program | Pattern/Segment | 40 pattern/600 segments |

- | |

| Segment time | Max. 999hours 59minutes 59seconds |

- | ||

| Function | Up/Down slope rate, Wait, Operating start code, Pattern name, Power stop mode, PT end mode |

- | ||

| Repetition | Pattern/Segment repeat operation |

- | ||

| PID control | PID groups | 6 PID groups(5 Zone PID groups + 1 Deviation PID group or 6 Seg PID groups) |

1 PID group/channel |

|

| Data back-up | Storage media | SD/SDHC card(FAT32 format) |

||

| Logging function | Program pattern/Parameter set data backup and recovery, available for sectional saving max. 6points out of main channel and sub channel PV |

|||

| Communication | Interface | Basic : Flexible to change between RS485/RS232C by DIP switch, Max. 31 nodes. Max. 115,200 bps, |

||

Option : Ethernet(TCP/IP) *In case of selection of ethernet, RS232C/485 is not available |

||||

| Power | Rated voltage | 24V DC 22VA Max. |

||

| Lithium battery | For setup data retention(CR2032) |

|||

Model code (TEMP2000M)

| Model | Additional code | Contents | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TEMP2 | □ | 0 | 0 | M | - | 0 | □ | / | □ | / | □ | / | □ | / | □ | |

| Size |

5 | 5.7inch (IP65 certification) |

||||||||||||||

| 7 | 7.5inch |

|||||||||||||||

I/O board |

0 | I/O1 (DO12points, DI16points) |

||||||||||||||

| 1 | I/O1, 2 (DO32points, DI16points) |

|||||||||||||||

SD card |

SD | SD card(ST'D) |

||||||||||||||

communication |

RS | RS232C/485(ST'D) |

||||||||||||||

| CE | Ethernet(TCP/IP) |

|||||||||||||||

Heater break alarm |

N | None |

||||||||||||||

| A | 50A |

|||||||||||||||

| B | 100A |

|||||||||||||||

| C | 12A |

|||||||||||||||

Sub channel |

CH2 | 2channels |

||||||||||||||

| CH4 | 4channels |

|||||||||||||||

| CH6 | 6channels |

|||||||||||||||

Model code (TEMP2000M Sub Channel)

| Model | Additional code | Contents | |||||||

|---|---|---|---|---|---|---|---|---|---|

| TEMP2 | 0 | 0 | 0 | M | / | □ | / | □ | |

Heater break alarm(ch1) |

N | None |

|||||||

| A | 50A |

||||||||

| B | 100A |

||||||||

| C | 12A |

||||||||

Heater break alarm(ch2) |

N | None |

|||||||

| A | 50A |

||||||||

| B | 100A |

||||||||

| C | 12A |

||||||||

| 1 | Manual | Instruction manual | |

| Communication manual | |||

| SIMS Manual | |||

| PME Manual | |||

| BitEditor Manual | |||

| 2 | Catalogue | Catalogue | |

| 3 | Dimension | Dimension | |

| 4 | Software | SIMS - Integrated communication software | |

| PME - Integrated parameter editor software | |||

| BitEditor - Image editor software | |||

| 5 | Executable file | SIMS, PME Additional files |