タッチタイププログラマブル熱衝撃試験コントローラー

TEMP2000S SERIES

As a thermal shock test controller, it supports high-quality TFT-LCD touch screen and recording function. This product supports the damper & elevator type.

-

Control method suitable for the system

Damper type, elevator type

-

Various types of pattern control

Provides various types of patterns in high temperature room, room temperature room, and low temperature room.High accuracy

-

Precision control with 18bit A/D convertor

±0.1% of full scale ±1 digit

-

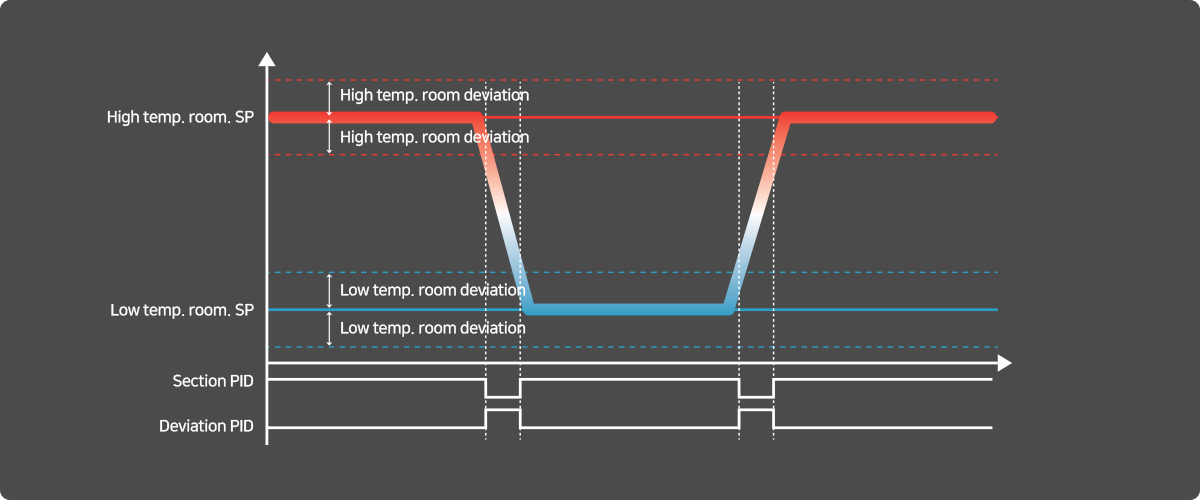

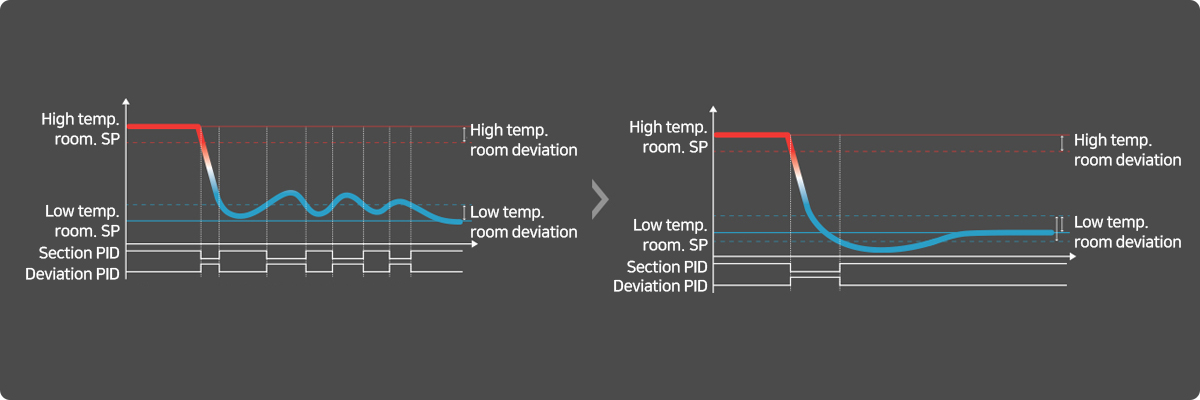

Variety of control PIDs

ZONE PID 3 and deviation PID 1 are applied for fast and stable control of sudden temperature rise and fall

-

Touch screen interface

Easy access to setup and operate with touch screen

-

Digital graphic recording function

Real-time monitoring & Data manage operation status of present value(Zone of experiment, High, Low) through full digital graph

-

SD memory card support

The pattern and parameter can be up/download via SD memory card

-

Multi-language system

Supporting of various languages of korean, english, Chinese, Japanese and russian

-

Standby type select

In case operation starts, select Standby-act(Pre-Heating, Pre-Cooling) & select conditions for standby-act cancel

-

Powerful communication

Basic include RS232C/485 serial communication (Communication speed 115,200bps) Ethernet support option

-

Various defrosting methods

Heater1 type(Defrosting during pre-set time), Hot-gas type, Manual type and heater2 type(Present value = Defrosting for set time from set value)

-

Free PC software

Free PC multi-monitoring software for communication and SD viewer for data management of SD data

Supporting SD memory card

-

Selectable Initial screen

User can choose appropriate initial screen

-

Editable Error Screen

Self-designed picture can be used

-

Electronic Album

Company and product profiles can be displayed

-

Data recording with SD card

Data acquisition of process value.

Up/Download parameter and pattern data.

Available for speedy and stable controlling on the rapid ascending/descending section

Available for preventing the initial hunting due to the lack of freezing capacity in low temperature room with adoption of low temp. room deviation hysteresis

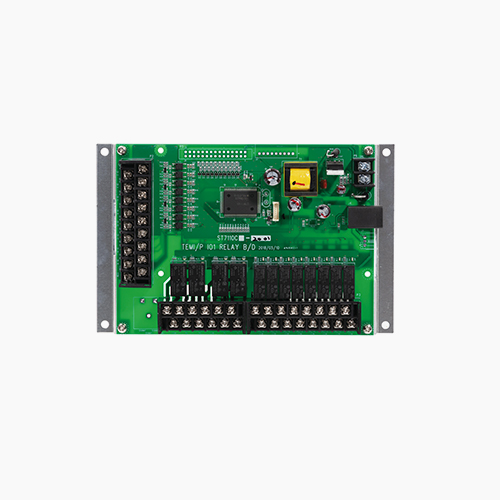

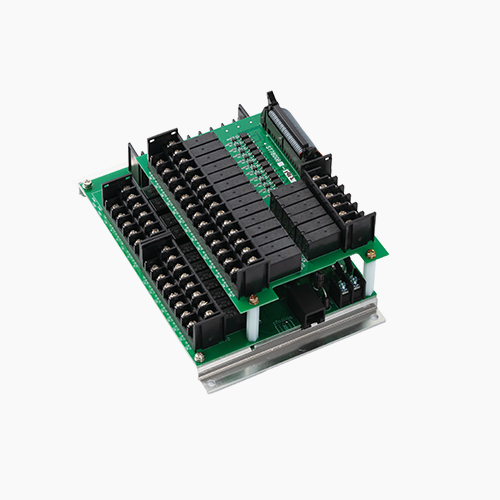

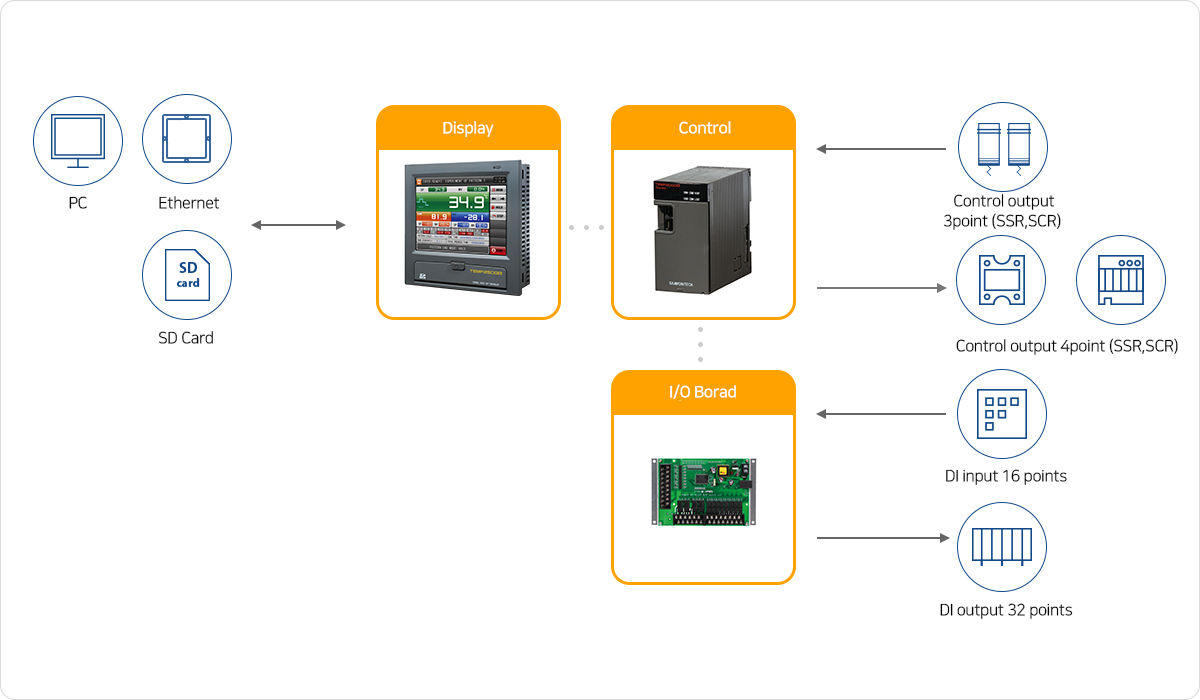

Separated hardware

Configuration separated by display, control, and input / output board

Available to mount panel mount and VESA mount

Various system configurations and work ability

| Group | Item | TEMP2500S | TEMP2700S |

|---|---|---|---|

| Screen | Display | 5.7" TFT-LCD |

7.5" TFT-LCD |

| Resolution | 640(W) × 480(H) |

||

| Language | English, Korean, Chinese/English, Korean, Japanese |

||

| User screen | Change of initial screen, Electronic album function |

||

| Mount type | PANEL mount, VESA mount(MIS-D 75) |

||

| Analog input | Input quantity | 3points(High temperature room, Low temperature room and laboratory room/Universal input) |

|

| Sensor type | TC |

K, J, E, T, R, B, S, L, N, U, W, Platinel Ⅱ, C |

|

| Sampling time | 500ms |

||

| Input accuracy | ±0.1% of full scale ±1 digit(A/D 18bits) |

||

| Analog output | Output specification (Max. 4points) |

Voltage output(SSR) 4points |

ON voltage 24V DC(Load resistor : Min. 600Ω/Pulse width : Min. 5ms) |

Current output(SCR) 4points |

4~20mA DC(Load resistor : Max. 600Ω) |

||

| Output type | Control output /Transmission output(High temperature room PV, Low temperature room PV and laboratory room PV) |

||

| Output accuracy | ±0.3%(D/A 14bits) |

||

| Digital input | Contact point specification | Basic 16points(Contact point capacity : Max. 12V DC, 10mA) Selection of operation for A or B point |

|

| Contact point function | Run/Stop/Hold/Step, selectable run patterns, set DI detect delay time, select DI error monitor(text or picture), damper sensing for high temp. room/Room temp. room/low temp. room |

||

| Digital output | Contact point quantity | Basic 12points(8points of A contact point relay + 4points of C contact point relay), Option add function(20point of A contact point relay) |

|

Normal open(Max. 30V DC/1A, 250V AC/1A), Normal close(Max. 30V DC/1A, 250V AC/1A) |

|||

| Signal type | Inner signal(8points) Time signal(4points) Alarm signal(4points) Ref signal(2points) Sensor open signal(3points) |

||

DI signal(16points) Manual signal(12points) Run signal(1point) Sol valve signal(1point) Run end signal(1point) |

|||

Logical signal(3points) Error signal(1point) Wait signal(2points) User signal(1points) N2 gas signal(1point) |

|||

Fan signal(3points) Damper signal(6points) Defrosting signal(1point) Experiment signal(3points) |

|||

| Program | Patterns | 120 patterns |

|

| Pattern type (6 types) |

① High temp. → Low temp./② Low temp. → High temp./③ Room temp. → High temp. → Room temp. → Low temp./④ Room temp. → Low temp. |

||

→ Room temp. → High temp./⑤ High temp. → Room temp. → Low temp. → Room temp./⑥ Low temp. → Room temp. → High temp. → Room temp. |

|||

| Repetition/Segment time | Max. 9999 times/999hours 59minutes 59seconds |

||

| Function | Wait, Pattern name, Power stop mode, PT end mode |

||

| Operation method | Operation specification | Damper, Elevator type |

|

| Defrosting method | Heater, Hot gas, Manual defrosting |

||

| PID control | PID groups | 4 PID groups(3 Zone PID groups + 1 Deviation PID group), *In case of applying the PID deviation, the Devation value of the high and low temp. room are applied separately |

|

| Data back-up | Storage media | SD/SDHC card(FAT32 format) |

|

| Logging function | Program pattern/Backup and recovery of parameter set data, Available for saving the indicated setting value for laboratory, High temperature room and low temperature room |

||

| Communication | Interface | Basic : Flexible to change between RS485/RS232C by DIP switch, Max. 31 nodes. Max. 115,200 bps, |

|

Option : Ethernet(TCP/IP) *In case of selection of ethernet, RS232C/485 is not available |

|||

| Power | Rated voltage | 24V DC 22VA Max. |

|

| Lithium battery | For setup data retention(CR2032) |

||

Model code

| Model | Additional code | Contents | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TEMP2 | □ | 0 | 0 | S | - | 0 | □ | / | □ | / | □ | |

| Size |

5 | 5.7inch (IP65 certification) |

||||||||||

| 7 | 7.5inch |

|||||||||||

I/O board |

0 | I/O1 (DO12points, DI16points) |

||||||||||

| 1 | I/O1, 2 (DO32points, DI16points) |

|||||||||||

SD card |

SD | SD card(ST'D) |

||||||||||

Ethernet communication |

- | None |

||||||||||

| CE | Ethernet(TCP/IP) |

|||||||||||

| 1 | Manual | Instruction manual | |

| Communication manual | |||

| SIMS Manual | |||

| PME Manual | |||

| BitEditor Manual | |||

| 2 | Catalogue | Catalogue | |

| 3 | Dimension | Dimension | |

| 4 | Software | SIMS - Integrated communication software | |

| PME - Integrated parameter editor software | |||

| BitEditor - Image editor software | |||

| 5 | Executable file | SIMS, PME Additional files |